Description

- OverviewEssential details

- Applicable Industries:

- Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Other

- Showroom Location:

- Viet Nam, Brazil, Pakistan, Nigeria, Uzbekistan, Malaysia

- Condition:

- New

- Type:

- Rotary

- Configuration:

- Stationary

- Power Source:

- AC POWER

- Lubrication Style:

- Oil-free

- Mute:

- NO

- Place of Origin:

- Shanghai, China

- Brand Name:

- Luoyou

- Model Number:

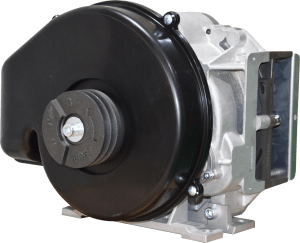

- LY-27.5VA

- Voltage:

- 380V/220V/110V (can be customized accordingly)

- Dimension(L*W*H):

- 1550*1170*1550mm

- Weight:

- 1080Kg

- Warranty:

- 1 Year

- Working Pressure:

- 8 bar, 10 bar

- Air capacity:

- 3.0 M3/min 106cfm

- Machinery Test Report:

- Provided

- Video outgoing-inspection:

- Provided

- Marketing Type:

- New Product 2022

- Warranty of core components:

- 2 years

- Core Components:

- PLC, Pressure vessel, Engine, Gear, Motor, Pump, Bearing, Gearbox

- Gas Type:

- Air

Supply Ability- 500 Set/Sets per Month

The scroll compressor is classified as a positive displacement compressor, which operates by compressing gas or air within a sealed system. The object in question comprises of two helical coils that revolve around a central axis through the aid of an electric motor. The scrolls are arranged in a manner that prevents them from making contact with each other. This arrangement results in the formation of pockets of air or gas between the scrolls, which subsequently become trapped and compressed toward the center of the scroll. The compressed gas or air is subsequently released through a valve to the intended application.

Scroll compressors are widely recognized for their exceptional efficiency, reliability, and minimal maintenance requirements. These devices are frequently utilized in air conditioning, refrigeration, and industrial settings where a consistent supply of compressed air or gas is necessary. This article aims to provide a comprehensive analysis of the operational mechanisms of scroll compressors, along with an evaluation of their strengths and limitations, and an exploration of their diverse range of applications.

The Operational Mechanism of Scroll CompressorsThe operational process of a scroll compressor can be segmented into four distinct stages, which are outlined below:

Drawing-in Stage

In this stage, the rotating scroll draws in the gas or air from the suction port. The pocket volume between the two scrolls experiences an increase as the rotating scroll moves away from the fixed scroll, resulting in the formation of a low-pressure zone. The low-pressure region induces the flow of gas or air from the suction port.

Compression Stage

After the gas or air is taken in, it becomes confined in the interstitial spaces between two scroll elements. As the pockets migrate toward the central region of the scroll, the volume of the pockets diminishes, resulting in the compression of the gas or air enclosed within. The compression process persists as the pockets progressively advance toward the central region of the scroll, culminating in the attainment of the maximum point of compression.

Discharge Stage

Once the compression reaches its maximum point, the compressed gas or air is released through a valve to fulfill the intended application. The opening of the discharge valve is triggered by the attainment of the requisite pressure level within the pocket’s volume, as per the specific application requirements.

Exhaust Stage

After the discharge of gas or air, the pocket shifts away from the central axis of the scroll, resulting in the formation of a region of reduced pressure. The presence of a low-pressure region facilitates the expansion of the pocket, thereby initiating the subsequent drawing-in stage.

The Advantages of Scroll Compressors

1. High-Efficiency Scroll compressors are recognized for their exceptional energy efficiency, which can be attributed to their distinctive design. In contrast to other compressor types, scroll compressors lack any clearance volume or dead space. This indicates the absence of any compressed air or gas leakage or recirculation. Consequently, scroll compressors have the capability to attain efficiency levels as high as 95%.

2. Low Noise and Vibration Scroll compressors exhibit low levels of noise and vibration during their operation. This phenomenon can be attributed to the seamless and uninterrupted motion of the scrolls, which stands in contrast to the jerky and pulsating movements commonly observed in reciprocating compressors. This characteristic renders them suitable for indoor settings and situations where noise and vibration pose a potential issue, such as medical facilities, educational institutions, and professional workplaces.

3. Low Maintenance Scroll compressors are characterized by a straightforward design with minimal moving components, resulting in low maintenance requirements. The scrolls in this system do not necessitate frequent lubrication since they do not come into contact with each other. This implies that the probability of experiencing wear and tear is minimized, thereby decreasing the necessity for frequent maintenance.

4. High Reliability The simple design of scroll compressors is their high reliability, which can be attributed to their simple design. The low vibration and stress levels of these compressors make them less susceptible to breakdowns and failures in comparison to other compressor types. This characteristic renders them well-suited for critical applications, particularly in the medical equipment industry, where any period of inactivity can result in significant financial losses.

5. Scroll compressors have a broad spectrum of applications, encompassing air conditioning, refrigeration, and industrial sectors. These devices are well-suited for use in air conditioning and refrigeration systems, as they provide a consistent flow of compressed air or gas. Compressed air or gas is utilized in various industrial applications, including food processing and packaging, where it is imperative that the medium is devoid of any impurities.

The utilization of Scroll Compressors in various industries and applications.

1. Air Conditioning and Refrigeration Scroll compressors is widespread in air conditioning and refrigeration systems. These applications are well-suited for these motors owing to their exceptional energy efficiency, minimal noise and vibration levels, and dependable performance. These devices find application in various settings including residential, commercial, and industrial environments such as supermarkets, hospitals, and hotels.

2. Industrial Applications Scroll compressors find extensive usage in various industrial applications, including but not limited to food processing, packaging, and pharmaceuticals. These applications utilize compressed air or gas to maintain the quality of manufactured products and therefore require a consistent flow of clean air or gas.

3. Scroll compressors find application in automotive air conditioning systems owing to their high energy efficiency and compact size. The utilization of these components is progressively becoming more common in electric and hybrid vehicles, particularly in light of the importance of energy efficiency in these types of vehicles.

Scroll compressors represent a distinctive category of compressors that offer exceptional energy efficiency, reduced noise, and vibration levels, minimal maintenance requirements, and high reliability. Due to their exceptional performance and versatility, these systems have found extensive use in various fields such as air conditioning, refrigeration, industrial, and automotive applications. Nonetheless, these technologies exhibit certain limitations, including restricted capacity and elevated initial expenses. In various applications, such as those that prioritize energy efficiency, reliability, and low noise and vibration levels, scroll compressors are a highly suitable option.

Available Models:

| Model | FAD m³/min | Power(KW) | Working Pressure(Mpa) | Outline Specification | Drive(pc) | Noise dB | Weight(KG) | Outlet Pipe |

| Scroll Compressor Only | ||||||||

| LY-1.5VA | 0.13 | 1.5 | 0.8/1.0 | 730*610*880 | 1*04 | 55±2 | 200 | ¾Ball Valve |

| LY-2.2VA | 0.24 | 2.2 | 0.8/1.0 | 730*610*880 | 1*06 | 55±2 | 220 | ¾Ball Valve |

| LY-3.7VA | 0.4 | 3.7 | 0.8/1.0 | 730*610*880 | 1*04 | 55±2 | 200 | ¾Ball Valve |

| LY-5.5VA | 0.6 | 5.5 | 0.8/1.0 | 730*610*880 | 1*06 | 58±2 | 210 | ¾Ball Valve |

| LY-7.5VA | 0.8 | 7.5 | 0.8/1.0 | 1170*700*1080 | 2*04 | 60±2 | 380 | 1″ |

| LY-11VA | 1.2 | 11 | 0.8/1.0 | 1170*700*1080 | 2*06 | 62±2 | 400 | 1″ |

| LY-15VA | 1.6 | 15 | 0.8/1.0 | 1170*700*1550 | 3*06 | 65±2 | 600 | 1″ |

| LY-16.5VA | 1.8 | 16.5 | 0.8/1.0 | 1170*700*1550 | 3*06 | 65±2 | 600 | 1″ |

| LY-18.5VA | 2.0 | 18.5 | 0.8/1.0 | 1550*1170*1075 | 4*06 | 68±2 | 800 | 1.5″ |

| LY-22VA | 2.4 | 22 | 0.8/1.0 | 1550*1170*1075 | 4*06 | 68±2 | 800 | 1.5″ |

| LY-27.5VA | 3 | 27.5 | 0.8/1.0 | 1550*1170*1550 | 5*06 | 70±2 | 1080 | 1.5″ |

| LY-30VA | 3.2 | 30 | 0.8/1.0 | 1550*1170*1550 | 5*06 | 70±2 | 1080 | 1.5″ |

| LY-33VA | 3.6 | 33 | 0.8/1.0 | 1550*1170*1550 | 6*06 | 70±2 | 1200 | 1.5″ |

| LY-38VA | 4.2 | 38 | 0.8/1.0 | 2320*1450*1700 | 7*06 | 72±2 | 1400 | 2.0″ |

| LY-44VA | 4.8 | 44 | 0.8/1.0 | 2320*1450*1700 | 8*06 | 72±2 | 1500 | 2.0″ |

| LY-49VA | 5.4 | 49 | 0.8/1.0 | 2320*1450*1700 | 9*06 | 72±2 | 1650 | 2.0″ |

| Scroll Compressor + Tank (T = Tank) | ||||||||

| LY-1.5VAT | 0.13 | 1.5 | 0.8/1.0 | 730*610*880 | 1*04 | 55±2 | 200 | ¾Ball Valve |

| LY-2.2VAT | 0.24 | 2.2 | 0.8/1.0 | 730*610*880 | 1*06 | 55±2 | 220 | ¾Ball Valve |

| LY-3.7VAT | 0.4 | 3.7 | 0.8/1.0 | 730*610*880 | 1*04 | 55±2 | 200 | ¾Ball Valve |

| LY-5.5VAT | 0.6 | 5.5 | 0.8/1.0 | 730*610*880 | 1*06 | 58±2 | 210 | ¾Ball Valve |

| LY-7.5VAT | 0.8 | 7.5 | 0.8/1.0 | 1170*700*1080 | 2*04 | 60±2 | 380 | 1″ |

| LY-11VAT | 1.2 | 11 | 0.8/1.0 | 1170*700*1080 | 2*06 | 62±2 | 400 | 1″ |

Our Services

Can’t find what you want?

Just try our Tailor-made service, simply tell us your needs,

and we can customize it for you to meet all your needs!

FAQ:

- Who are we?

We are a compressor manufacturer factory in Shanghai.

- Why choose us?

With Excellent Design, Advanced Technology, and a well-known reputation in both domestic and overseas markets, we are much confident in our products’ quality and service.

- What are the payment terms?

We accept T/T, L/C, D/P, Western Union, Paypal, and Credit Cards.

- Delivery

Lead Time could be limited to as less as 7 days for conventional products.

- Can products be customized?

We can alter, re-design and reassemble products to meet clients’ requirements upon request.

Packaging & Shipping

Standard packing with wooden case for international transportation.

Port of Loading: Shanghai, China

Price on FOB Shanghai Basis, overseas freight and insurance costs upon inquiries.

Reviews

There are no reviews yet.